Ok, to expand on the whole thing:

Diesels locomotives in the US are diesel-electric. What this means is that the diesel engine literally just spins a big generator. This generator makes electricity, which then gets routed to traction motors, which are mounted on the trucks. It's those motors that actually move the train.

Diesel engines have narrow powerbands, and let's face it, a 3,000 HP transmission's gonna be a big thing, so, it's just easier to turn it into electricity.

There are some types of locomotives in Europe that are diesel hydraulic - much different. But they're a minority.

Diesels are often called AC or DC. What this means is the type of electricity that's fed into the traction motors, DC is the older technology, but the TMs require brushes and commutators, which wear down and are vulnerable to dirt. AC's newer - it's brushless, so the motor has only the rotor as a single moving part. But you need electronics to flip the power around to create the rotating field that spins the rotor. Both use century old motor technology, but it took until recently to get the electronics that make AC work for locomotives. Since AC uses a simpler motor, they require less motor maintenance, but they cost more to buy - that gap's narrowing fast though.

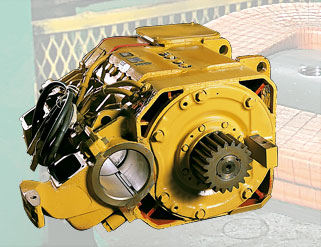

There's a few ways to mount the traction motors. The most popular in the US is have them rest partly on the axles and partly on the truck frame. It's good for low speeds and heavy duty applications, but it's rough on the track at high speeds. Much of Europe, and the electric units in the Northeastern US, the traction motors are supported entirely by the trucks, and couple to the wheels via a flexible coupling. This is easier on the track, but costs more and has a maintenance premium. For high speed applications (and some other special applications), the traction motors are mounted to the car/locomotive body, and drive the gearbox and wheels via a driveshaft. The Pendolino uses a setup that looks kind of like a rear wheel drive car (or an RDC), the TGV has the motor in the 'normal' location, but mounted to the body, and has a CV joint to the gearbox. This gives them a very light truck, which gives high speed stability and safety.

For a number of years, the French used a 'monomotor' design, where each truck had only one motor, geared to all the axles. This gave them somewhat better adhesion, but restricted axle movement, so it demanded very smooth track - that's why the French unit tested in the 70's on the NEC was such a dud. The AEM-7 has a motor per axle, and a very flexible truck that doesn't mind our track.

Traction motors typically have blowers mounted in the locomotive to keep air going through them. High power levels generate heat, and it's a limiting factor, especially a low speeds.

Dynamic braking means the motors are turned into generators to make electricity. This power's routed to resistors, or on some new electric locomotives, back out through the overhead wires. Contrary to what some believe, the motors are NOT 'put into reverse'. The actual mechanisms for how they are made to generate electricity are different between AC and DC - AC's done via some electronic slight of hands, DC's done by changing the connections around with automatic switches. AC has the advantage here - a good AC locomotive can provide dynamic to very low speeds, and in fact, some multiple unit trains (like subways) can actually come to a near stop with just motors alone. Diesel locomotives tend to have blowers to help cool their resistors, and those can be loud, since it takes a lot of air to cool things off. Dynamic used to be an option, but I'm pretty sure it's standard on everything now.

As surprising as it may sound, traction motors aren't actually that powerful in the world of electric motors - pumps at large water or sewage plants can easily have motors rated over 2,000 HP, and nuclear plants have pumps with motors rated upwards of 10,000 HP per pump (!). Those things are big - the size of a UPS truck, or bigger.