by green_elite_cab

I have a pantograph project, and its making me insane.

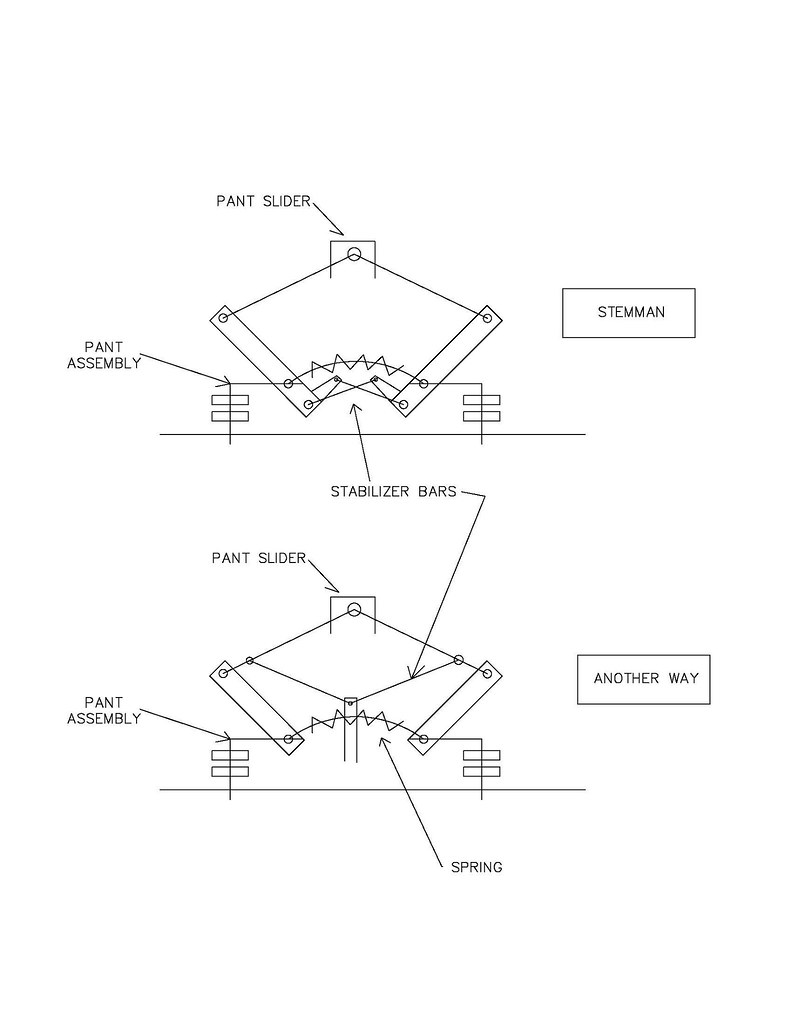

I'm build a stemman style pantograph, used on the Jersey Arrow MUs and many Metroliner cars. The arms weren't to hard, and i just figured out how to build the base of the pantographs accurately. However, I'm having problems with the equalizer bars.

Diamond shaped pantographs need two of these. they keep the arms folding in sequence. However, i can't seem to find a the right length for them, and when i think i do, the mountings for the equalizer bars tend to pull off, showing they are too tight.

does anyone have any experience with such a model?

I'm build a stemman style pantograph, used on the Jersey Arrow MUs and many Metroliner cars. The arms weren't to hard, and i just figured out how to build the base of the pantographs accurately. However, I'm having problems with the equalizer bars.

Diamond shaped pantographs need two of these. they keep the arms folding in sequence. However, i can't seem to find a the right length for them, and when i think i do, the mountings for the equalizer bars tend to pull off, showing they are too tight.

does anyone have any experience with such a model?

Elite Juice Jack Modeler.